Digital Twins

How UK Air Comms creates Digital Twins using Drone Technology.

UK Air Comms and Digital Twins

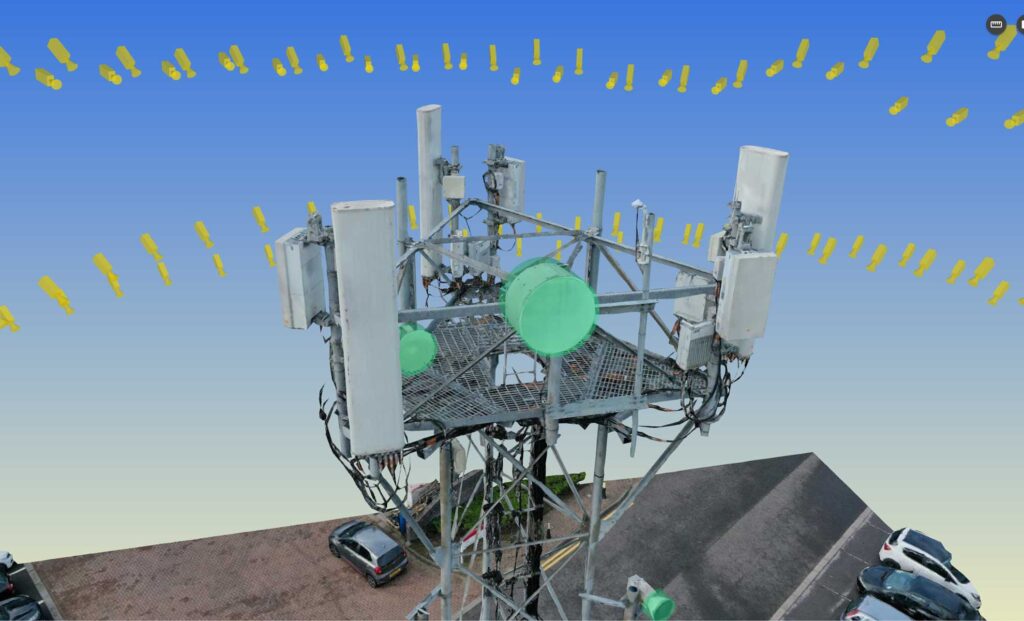

We can produce 3D interactive models, allowing you to measure any brace, cable route, compound, head frame or other mast components. Thus reducing time spent searching for hardware drawings and measurements that may be outdated. Our combination of specialist equipment, highly trained UAV operators and software solutions allow us to create Digital Twins accurate to within 2cm.

Creating a Digital Twin is a very efficient and accurate way of surveying your assets. We no longer require a team of surveyors, designers, health and safety supervisors and expensive access equipment to survey hard-to-reach assets such as telecoms masts and pylons. With the combination of our drone, laser measuring and photography equipment, UK Air Comms is able to provide you with a bespoke 3D model of your asset, accessible to you and your team of professionals from the comfort of your own desks.

Frequently Asked Questions about Digital Twins

A digital twin is basically a 3D model of any real-life object. It’s the virtual representation of any given real-time object (or process or service). A digital twin could also be combined with data sources such as sensors or manually inputted data to produce what is known as an IoT (Internet of Things) Digital Twin that can then be used to monitor processes and simulate different situations. The digital twin concept consists of three distinct parts: the physical product, the digital/virtual product, and connections between the two products. The IoT Digital Twins have fast become the way forward in designing and monitoring all kinds of systems from manufacturing to agricultural to medicinal.

The concept and model of the digital twin was publicly introduced in 2002 by Professor Michael Grieves at a Society of Manufacturing Engineers conference in Michigan. Grieves proposed the digital twin as the conceptual model underlying product lifecycle management (PLM). Although at the time it was a known concept under different labels, it wasn’t until 2010 when Nasa coined the phrase “Digital Twin” when they were working on the concept to improve their manufacturing processes.

Digital Twins are used in a lot of industries these days. Industries including construction, urban planning, agriculture, manufacturing, telecommunications, asset management, mining, healthcare and more. Creating a digital twin of a product, asset, process or service all achieve the same thing – a more cost-efficient, time-saving and accurate way to design, create and improve any product, asset, process or service. The surge in IoT (Internet of Things) means that a collosal amount of data can be captured and applied in layers to any digital twin in order to simulate different situations.

Digital Twins in Telecoms

To give an example specific to the telecommunications industry right now would be the use of digital twins in creating interactive 3D models of telecommunication masts. UK Air Comms have become the largest provider in the UK for digital twins of telecoms masts. Our interactive models allow design teams to inspect hundreds of sites remotely in order to monitor things like the condition of the masts and if they are suitable for upgrades from 4G to 5G. Our Line of Sight service even allows telecoms businesses to map where to place new masts to improve coverage.

Digital Twins for Construction

UK Air Comms are able to produce accurate models of construction sites including groundworks and buildings. This can play a vital role in documenting the progress of any construction project. All the surveys, designs, and measurements can be monitored at any time, remotely by the whole project team.

So how do you create a Digital Twin? here at UK Air Comms, we specialise in capturing data with the use of a combination of groundwork techniques and UAV’s (drones). Our specialist surveying equipment and highly-trained UAV Operators are able to capture images and accurate measurements using LiDAR technology. The data they capture is then carefully processed using specialist software to build an interactive, comprehensive project file that is tailored to the clients’ needs.

It is dificult to give a fixed cost to the average digital twin project. It depends on how accessible the site is, how big the asset is and what data is needed in the project file. If you think you or your company would benefit from Digital Twin technology, please get in touch with our team. We will work on creating a solution for your project and get back to you with prices and timescales. We work with the three big Network Providers in the UK amongst other large organisations so we should be able to provide you with a solution to your digital twin needs.

Ready to get started?

Let’s talk about how we can help you and your business.